MATERIALS.CO.UK

Metals • Plastics • Rubbers • Polymers • Ceramics • Composites

Metals • Plastics • Rubbers • Polymers • Ceramics • Composites

Metals • Plastics • Rubbers • Polymers • Ceramics • Composites • Coatings

RESIDUAL STRESS IN BRASS & COPPER ALLOYS

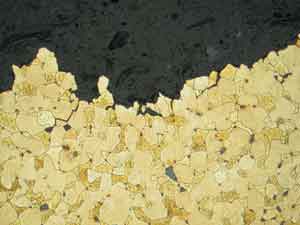

Stress corrosion cracking (SCC) is a failure mechanism resulting from the combination of a tensile stress (which could be residual stress) and an environment to which the alloy is chemically susceptible.

A component may fracture by SCC at relatively mild stress levels, including those resulting from residual stress, and in relatively mild environments. Minor variations in an environment, either chemically or temperature related, can lead to cracking, hence the need to understand and thereby minimise residual stress in a product.

Test

This test detects residual stresses in wrought copper alloy (eg brass) products that might result in failure due to stress corrosion cracking (SCC).

Stress corrosion cracking failure in

brass alloy component

Specification

| Solution | 10.7g HgNO3.H2O or 11.4g HgNO3.2H2O and 10ml of HNO3 per 1000ml of solution |

| Sample preparation | Deburr. Degrease. Pickle. Wash |

| Test temperature | Room temperature |

| Test duration | 30 minutes |

| Sample | Wash. Remove excess mercury |

| Sample assessment | Examine visually for cracks |

Standards

| ASTM B154:2016 | Standard Test Method for Mercurous Nitrate Test for Copper Alloys |