MATERIALS.CO.UK

Metals • Plastics • Rubbers • Polymers • Ceramics • Composites

Metals • Plastics • Rubbers • Polymers • Ceramics • Composites

Metals • Plastics • Rubbers • Polymers • Ceramics • Composites • Coatings

PAINT ADHESION

Description

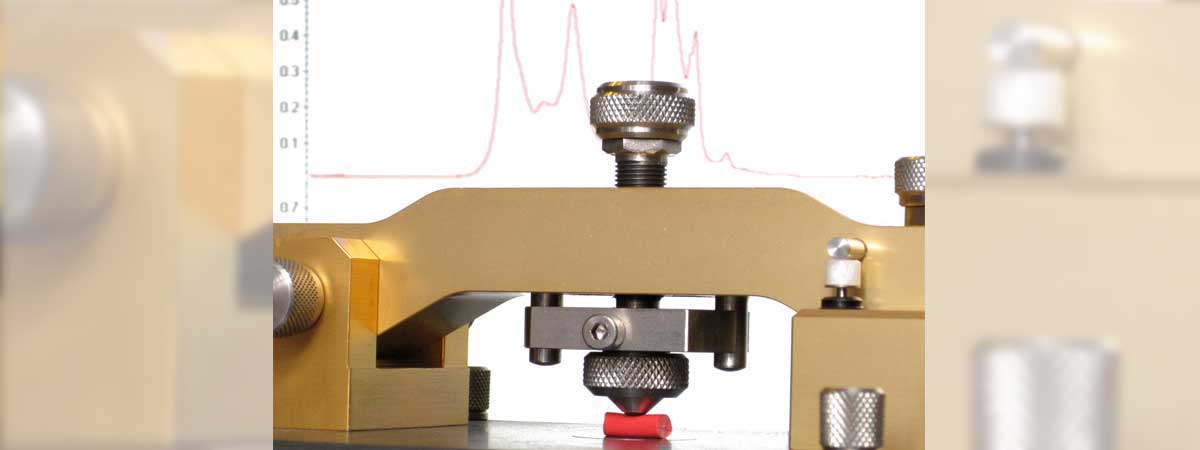

The Elcometer cross hatch cutter is a simple means of assessing the adhesion or resistance to separation of coatings from substrates.

The cutter, which has of a number of blades at equal spacing, is used to score through the coating down to the substate. Two cuts are made at right angles to each other resulting in a grid of small squares. Debris is removed from the surface of the sample and then adhesive tape is applied over the grid.

After removal of the tape, the coating adhesion is assesed by reference to charts shown in the relevant standard.

Elcometer Cross Hatch Cutter

Specification

| ASTM D 3359 - Metal Substrates | ||

| Coating thickness (µm) | Cut spacing (mm) | Number of cuts |

| 0 to 50 | 1 | 11 |

| 50 to 125 | 2 | 6 |

| >125 | >5 |

| ISO 2409 - Hard Substrates (metal) | ||

| Coating thickness (µm) | Cut spacing (mm) | Number of cuts |

| 0 to 60 | 1 | 6 |

| 61 to 120 | 2 | 6 |

| 121 to 250 | 3 | 6 |

| ISO 2409 - Soft Substrates (wood, plaster) | ||

| Coating thickness (µm) | Cut spacing (mm) | Number of cuts |

| 0 to 60 | 2 | 6 |

| 61 to 120 | 2 | 6 |

| 121 to 250 | 3 | 6 |

Standards

| ASTM D3359-17 | Standard Test Methods for Measuring Adhesion by Tape Test |

| BS EN ISO2409:2013 (BS 3900-E6:1992) | Paints and varnishes. Cross-cut test |