METALS FAILURE ANALYSIS

Operating since 2000, Inspiratech have wide experience of investigating metal component failures. We are highly qualified scientists and engineers with industrial experience gained in the research, automotive, oil and gas and industrial sectors. Our independent laboratories offer a comprehensive range of techniques to determine the root cause of failure including:

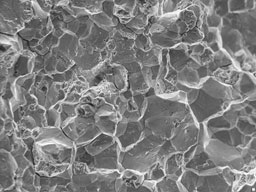

- Scanning electron microscopy

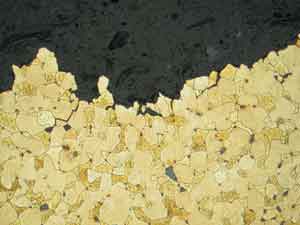

- Optical microscopy

- Macroscopy

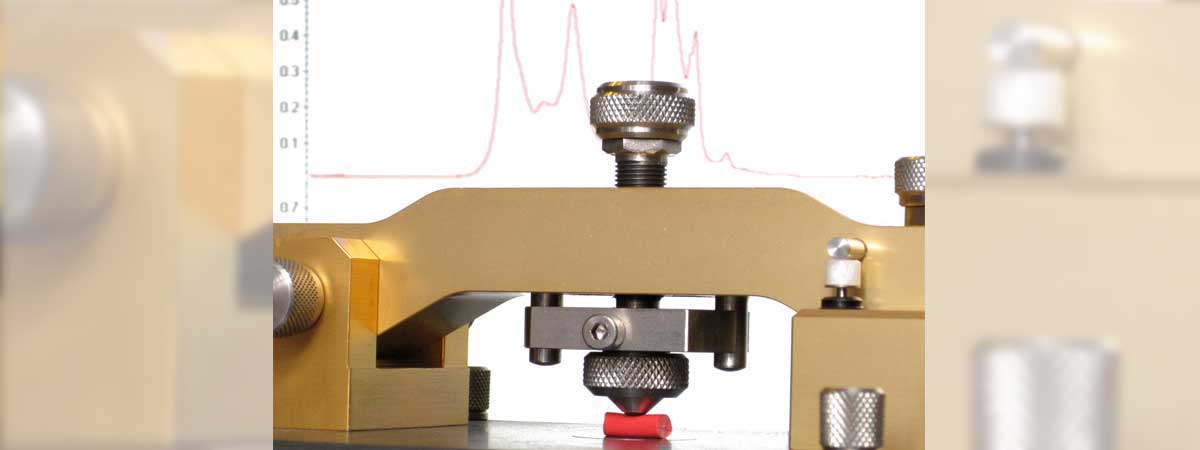

- Chemical analysis/FTIR

- Microhardness testing

- Dye penetrant testing

We provide a confidential, reliable and competitive service to meet our customers needs, offering our expert support and advice together with skilled investigation and reporting.

Determining the root cause of why a component fails or does not meet its required performance expectations requires a series of tailored investigative steps. Fundamentally, there are four ways in which metals fail: fracture, corrosion, wear and deformation. In practice, however, the reasons for metal failures may be less obvious. Some common causes of failure are:- Incorrect material choice

- Defects in the material, such as inclusions, porosity and cracks

- Incorrect heat treatment

- Stress concentrations caused by poor design or incorrect machining

- Mechanical overload

- Fatigue

- Corrosion

- Stress corrosion cracking

- Hydrogen embrittlement

- Oxidation

- Wear

- Fretting

A comprehensive report from our independent laboratories can identify such causes that may have arisen from design, materials selection, processing or service conditions/environment and provide recommendations for the necessary corrective actions to give improved reliability and performance.