Analysis of Particles & Contaminants

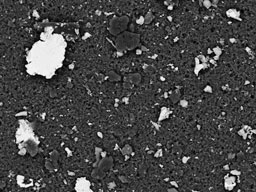

Scanning electron microscopy is an effective method to analyse:

- Dust particles

- Filter debris

- Mineral and metallic contaminants

- Fibres

- Food contaminants

- Grinding, grit blasting and welding debris

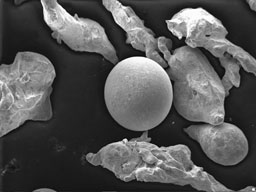

A scanning electron microscope (SEM) uses an electron beam, rather than light, to interact with atoms in the sample, producing information about the surface morphology and composition of the sample.

The ability to image and analyse individual particles can provide useful information to identify the source of such particulate and hence determine any necessary preventative measures. For example, a particular grade of stainless steel present as machining swarf; globular welding spatter; embedded wear debris; glass fragments with fine, identifying, embossed details; mineral contamination at an adhesive joint, are typical of the detailed information that can be elicited.

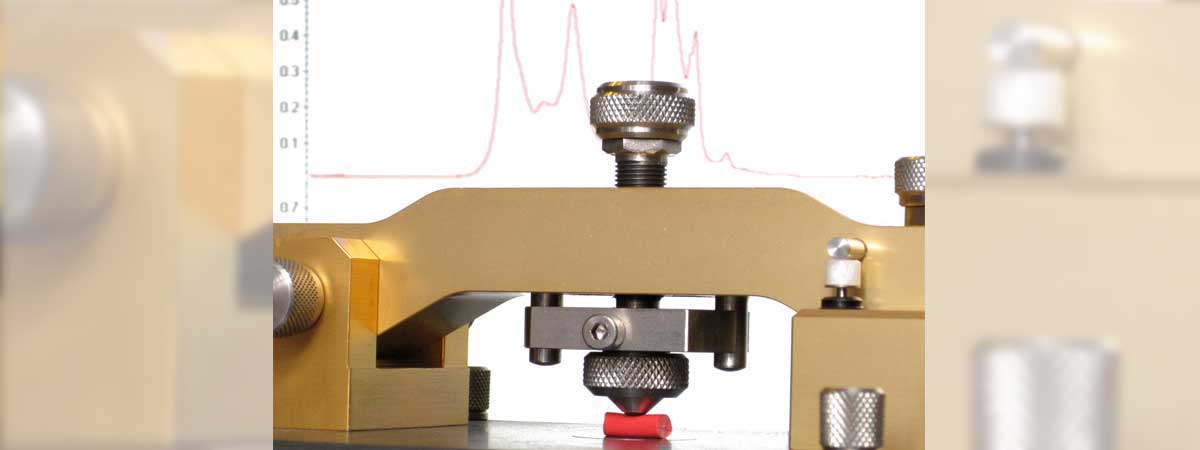

Our LEO 435VP is a high-performance, variable pressure scanning electron microscope with a resolution of 4nm. Secondary and back-scattered detectors allow for examination of surface topography together with compositional information. Coupled with a thin-window detector Oxford Isis 300 EDS system, it can be used for the simultaneous analysis of elements from boron to uranium.

We offer a confidential and competitive service, expert support and advice together with comprehensive reporting.